ADA KEMEWAHAN DI SETIAP SUDUTNYA

Selamat datang di Marina Bay Sands, sebuah destinasi markah di pusat kota Singapura dan wilayah teluk yang ramai. Sebuah selebrasi dari selera dan kemewahan tiada tanding, juga disandingi layanan luar biasa, penuh perhatian, dan sempurna. Di sana, semua detail mencerminkan kepuasan.

Nikmati gemerlap kota dari infinity pool yang mendunia dan benamkan diri Anda dalam jagat dengan kemungkinan tiada batas. Berbelanja, bersantap, bermain, menginap, dan masih banyak lagi ― Semuanya ada dalam satu destinasi luar biasa ini. Tidak ada lagi tempat seperti ini di dunia.

KAMAR & SUITE

KAMAR & SUITE

Dirancang dengan intuisi untuk membuat Anda merasa nyaman, tenang, senang, serta gembira, kamar dan suite kami adalah surga nan damai di tengah keramaian kota.

Bangun disambut pemandangan spektakuler. Berenang di tepi cakrawala infinity pool teras atap terbesar di dunia. Lepaskan kekhawatiran karena semua kebutuhan dan keinginan tersaji di hadapan Anda.

BERSANTAP

Jelajahi petualangan kuliner yang menyajikan beragam pilihan hidangan, dibuat dari bahan-bahan terbaik dan dimasak sepenuh hati. Kreasi unik dan elok dari chef terkenal di restoran peraih penghargaan kami akan membuat eksplorasi boga Anda sempurna.

BERBELANJA

Telusuri koleksi terkurasi paling baru musim ini dari rumah mode, serta merek gaya hidup dan kecantikan paling bergengsi di dunia. Mulai dari adibusana hingga jam tangan kelas atas, perhiasan mewah hingga wine langka, nikmati koleksi yang mencerminkan selera dan gaya paling anggun.

PENGALAMAN

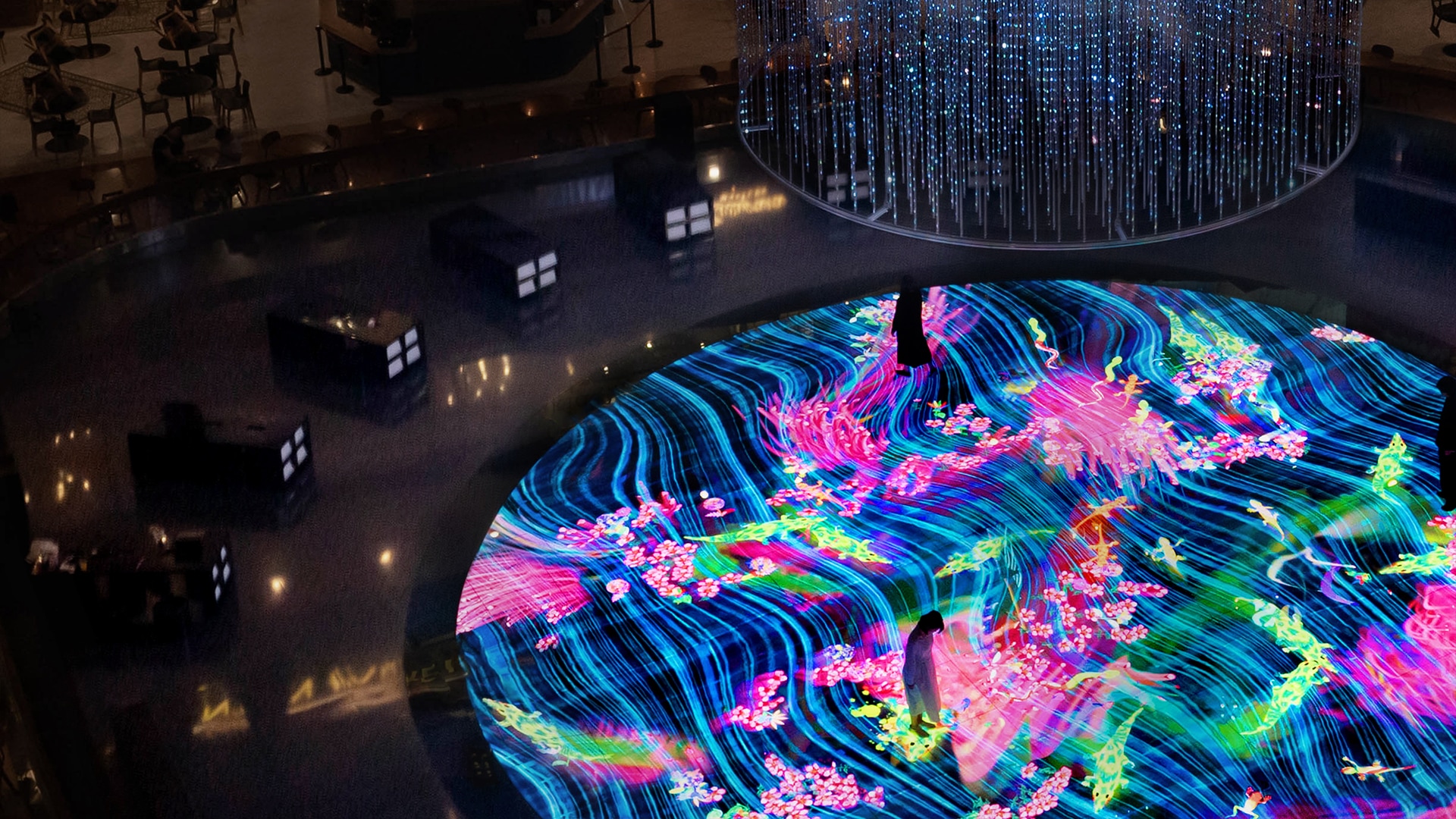

Jelajahi pameran yang menghanyutkan, tonton pertunjukan teater dan konser kelas dunia, atau susuri kanal di atas perahu Sampan tradisional. Selain itu, agenda sepanjang tahun berisi festival yang dikurasi secara cermat serta program budaya bagi seniman, musisi, dan desainer menjadikan Marina Bay Sands surga inspirasi dan eksplorasi.

HIBURAN MALAM

Di Marina Bay Sands, malam tidak pernah berakhir. Teguk koktail karya peracik minuman di bar teras atap terbuka lantai 57 dan bergoyang di kelab malam terbesar Singapura, tempat DJ internasional memutar musik pembangkit semangat agar pesta terus berlangsung hingga matahari terbit.

SANDS LIFESTYLE

Jadikan kunjungan Anda berkesan ― bergabunglah ke dalam program reward paling melimpah di Singapura. Dapatkan reward tanpa batas secara langsung saat Anda berbelanja, bersantap, bermain, dan menginap di Marina Bay Sands, juga nikmati keistimewaan lebih besar saat Anda memanjakan diri.

Anggota terhormat kami dapat menikmati akses prioritas ke acara dan restoran yang banyak diburu, serta undangan eksklusif ke pengalaman gaya hidup yang dikurasi secara unik.